1. Ethical Fiber Collection

During the spring molting season, our herders carefully hand-comb the soft undercoat from free-grazing goats, ensuring no harm or stress to the animals. This traditional method preserves fiber

integrity and length while prioritizing animal welfare, resulting in raw cashmere that is both luxuriously soft and sustainably sourced.

FINEAST Standard of Manufacturing

2. Hand Sorting

Skilled artisans meticulously examine and categorize the raw cashmere by length, fineness, and color, rigorously selecting only the longest, softest fibers under 16.2 microns. This labor-intensive process ensures consistency, superior quality, and the exceptional smoothness and durability that define our luxury garments.

3. Impurity Removal

Expert workers meticulously inspect each batch of cashmere, carefully picking out any coarse hairs, dust, or natural debris by hand. This thorough cleaning process guarantees that only the softest, most uniform fibers remain, laying the foundation for the flawless texture and premium quality of our final products.

4. Deep Cleaning

The raw cashmere undergoes a precise mechanical opening and cleaning process, where advanced, gentle machines loosen

and eliminate deeply embedded impurities like sand, dust, and organic residues without damaging the delicate fibers. This step ensures the material remains pure, soft, and ready for spinning while maintaining its natural integrity.

5. Gentle Washing

The fibers undergo a carefully controlled washing process using mild, eco-friendly detergents and purified water to eliminate any remaining dirt, natural oils, and odors. This step includes gentle disinfection to meet strict hygiene standards while preserving the cashmere’s softness, loft, and natural properties, ensuring a clean and safe material for further production.

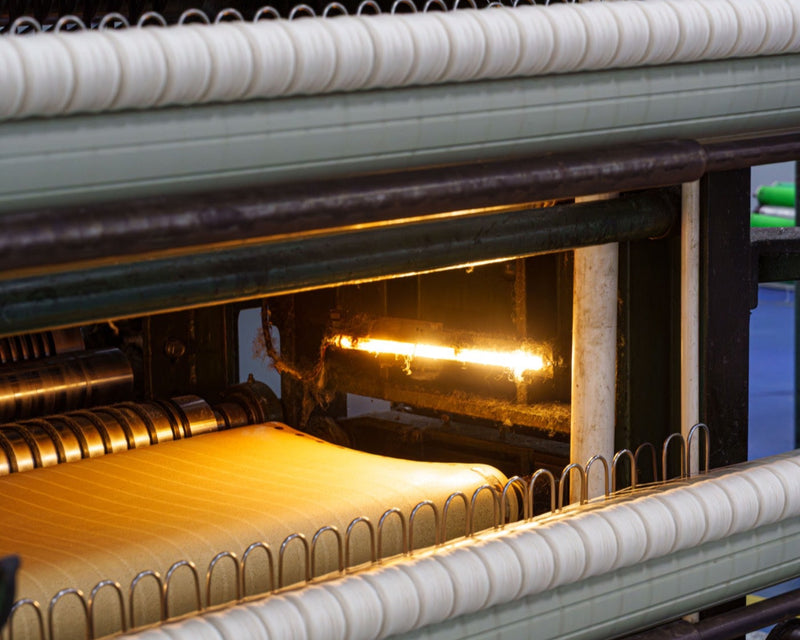

6. Low-Temperature Drying

The cleaned cashmere is carefully dried using low-temperature, energy-efficient airflow systems that prevent fiber damage or shrinkage. This controlled process maintains the natural softness and loft of the cashmere while ensuring optimal moisture removal, resulting in fluffy, residue-free fibers ready for the next stage of production.

7. Secondary Inspection

After drying, experienced artisans meticulously re-examine each batch of cashmere, removing any remaining inconsistent fibers or minor imperfections overlooked in previous stages. This rigorous secondary selection guarantees only the most uniform, premium-quality fibers advance, reinforcing our commitment to exceptional softness, purity, and durability in the final product.

8. Fiber Blending

Specialized machinery gently mixes selected cashmere fibers with other complementary materials (if applicable) in precise proportions, achieving an even distribution of thickness, length, and color.

This controlled blending process enhances the yarn’s structural integrity, softness, and performance, creating a balanced and high-quality material ready for spinning.

9.Fiber Conditioning

A carefully measured blend of water and natural, fiber-friendly oils is evenly applied to the cashmere to restore elasticity, reduce static, and improve cohesion. This conditioning step ensures smoother, more consistent spinning by reducing breakage and enhancing the workability of the fibers without compromising their natural softness or eco-friendly properties.

10.Precision Carding

Advanced mechanical carding machines gently process the fibers, using fine-toothed rollers to meticulously isolate the soft cashmere from any remaining coarse wool or impurities. This precision technique guarantees exceptionally pure, smooth, and uniform cashmere clusters, ready for high-quality spinning while maintaining the integrity and luxury of the material.

11.No Dyeing

Unlike conventional dyeing processes that often use harsh chemicals, synthetic pigments, and excessive water—leading to fiber damage, color fading, and environmental pollution—we embrace the cashmere’s innate shades. By avoiding dyes, we maintain the fiber’s exceptional softness, strength, and breathability, while ensuring a hypoallergenic, sustainable product that honors both nature and your comfort.

12. Fine Spinning

During the spinning stage, the carded

cashmere sliver is drafted, twisted, and thinned under controlled tension to form a uniform single yarn. Using optimized parameters—such as a draft ratio of 1.30–1.35 and spindle speeds around 5500 RPM—we achieve the desired yarn count, strength, and smoothness, ensuring the resulting yarn is both durable and luxuriously soft for high-quality knitting.

13. Yarn Winding

The single yarn is evenly wound onto

standardized cones or bobbins using automated precision winding machines. This process eliminates weak spots, reduces yarn breaks, and ensures consistent tension and density—optimizing the yarn for efficient, high-speed knitting or

weaving while maintaining its softness and structural integrity.

14. Yarn Plying

Two or more single yarns are twisted together in a controlled, balanced direction (typically Z-twist or S-twist) using specialized plying machinery. This process improves yarn durability, reduces pilling, and creates a smoother, more consistent thickness—resulting in a cohesive multi-strand yarn ready for weaving or knitting with enhanced resilience and a refined finish.

15. Twist Boosting

Using precision twisting machinery, yarns undergo a controlled twisting process that enhances tensile strength, reduces hairiness, and improves overall cohesion. The twist level—measured in twists per meter (TPM)—is carefully calibrated to balance softness and durability, ensuring the yarn remains smooth, uniform, and optimized for high-quality fabric production.

16. Precision Knitting

Computer-controlled knitting machines

seamlessly transform the plied yarn into garment panels with consistent tension, stitch density, and shape accuracy. This automated process ensures minimal yarn waste, uniform texture, and flawless structural integrity—resulting in soft, durable, and well-fitting cashmere products ready for finishing.

17. Fabric Inspection

Each fabric swatch undergoes multi-level inspections for key parameters: fiber fineness (maintained under 15.5 microns),

uniform weave density, color consistency, and absence of pilling or defects. We also test for tensile strength and shrinkage rate to verify compliance with luxury standards. This thorough process guarantees that every batch meets our requirements for exceptional hand-feel, performance, and longevity.

18.Seamless Assembly

Using specialized linking machines, skilled

technicians meticulously join individually knitted panels—such as sleeves, fronts, and backs—by accurately aligning stitches and employing reinforced, nearly invisible seams. This technique preserves the fabric’s elasticity, ensures smooth transitions between sections, and enhances the garment’s overall durability, comfort, and polished appearance.

19. Hand Finishing

Skilled artisans hand-stitch critical components such as cuffs, hems, collars, plackets, underarm reinforcements, and

pockets to ensure flawless alignment, flexibility, and durability. This technique allows for subtle adjustments that machines cannot achieve, preserving the garment’s natural drape, comfort, and refined appearance while maintaining structural integrity in high-stress areas.

20.Softening Process

The knitted garment is treated with a

controlled process of warm water, mild agitation, and natural lubricants (like organic soap) to lightly felt the fibers. This carefully monitored step closes gaps between stitches, increases fabric density, and lifts a delicate nap—resulting in a plumper, softer, and more luxurious hand-feel without compromising breathability or shape.

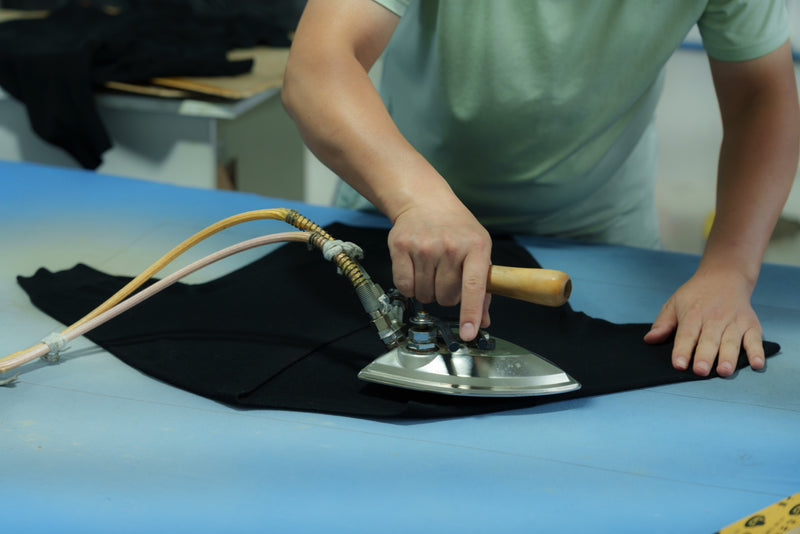

21. Steam Pressing

Using specialized steam ironing equipment and custom-shaped boards, we carefully smooth and set the cashmere garment’s

structure at controlled temperatures. This process eliminates wrinkles, evens out the surface texture, fixes the desired silhouette, and enhances the fabric’s natural loft—resulting in a crisp, refined appearance with lasting shape stability and comfort.

22. Surface Brushing

Using soft, natural-bristle brushes or specialized napping machines, we carefully raise the cashmere’s surface to create a uniform, velvety nap. This delicate process enhances the fabric’s loft, smoothness, and tactile comfort while removing any loose fibers—resulting in a consistently plush, luxurious hand-feel without compromising the garment’s structure or durability.

23. Final Inspection

In our quality inspection process, we

meticulously perform two key steps: hand-picking and light inspection. Hand-picking involves carefully examining each garment for flaws such as stains, color inconsistencies, or foreign fibers, using tweezers to remove impurities and adhesive tape to eliminate loose fibers—always starting from the inner side to protect the fabric’s surface. Light inspection follows under focused lighting, where artisans identify and repair even the subtlest imperfections.

24. Eco-Friendly Packaging

Each cashmere garment is gently folded,

wrapped in soft, acid-free tissue paper, and placed in a sturdy, recyclable gift box made from FSC-certified paper. The packaging not only protects the product during shipping but also reflects our brand’s commitment to luxury, responsibility, and thoughtful presentation.